WELCOME TO Sichuan Techairs Co., Ltd.

Sichuan Techairs Co., Ltd. (formerly known as “Yalian Technology”) operates as a high-tech enterprise specialized in R&D and engineering transformation of gas production, separation and purification technologies. The Company’s technology scope mainly covers temperature swing adsorption, pressure swing adsorption, wet process, shallow cooling, copious cooling, rectification and other gas separation.

skid-mounted device

High-Quality Project Contractor

Techairs has provided more than 600 (EPC, EP, E) sets of technology and equipment at home and abroad, including Britain, Japan, Korea, Thailand, Pakistan, Malaysia and so on.

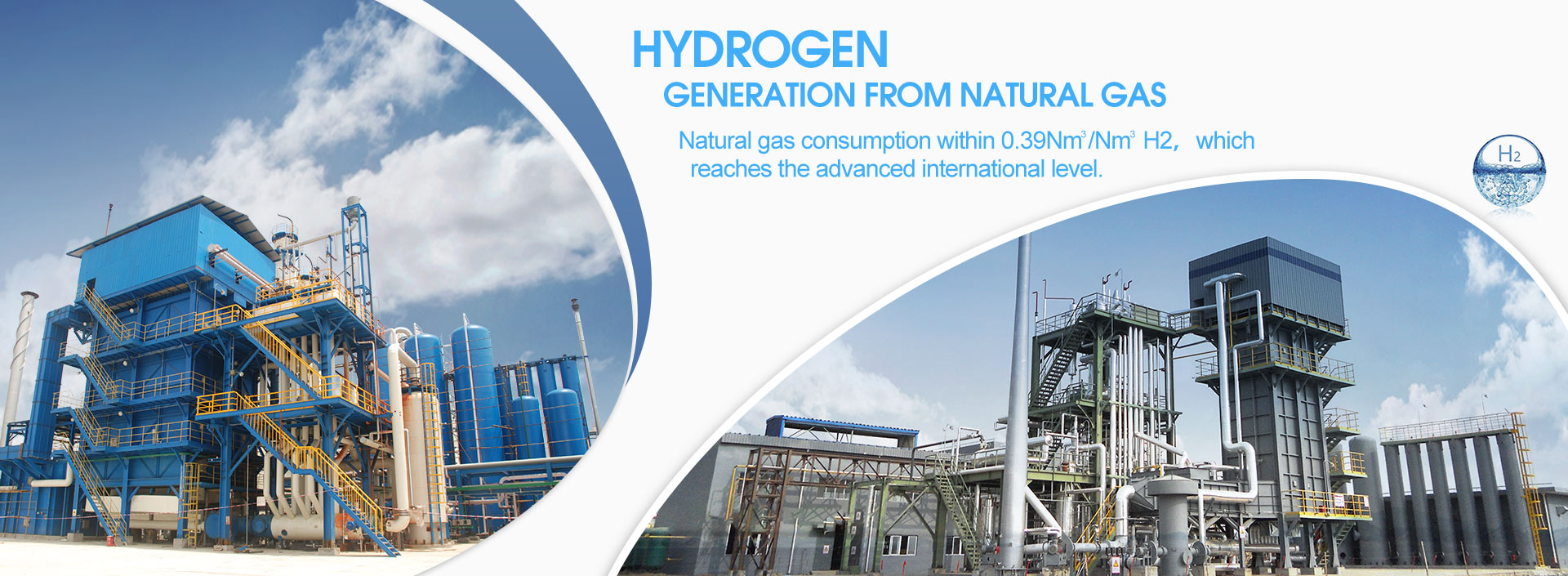

Hydrogen generation device